Thermodynamic System and Evaporator Heat Transfer Analysis of Nanoparticles-Based Additive in Chillers with Next-Generation Refrigerants

Problem:

The client was evaluating a new nanoparticles-based additive to be added to the chilled water of centrifugal chillers. The objective of the project was to compare baseline electricity usage in such chillers vs. an operational case wherein the fluid in the chilled water loop (water side of the evaporator) has both an increased heat transfer coefficient and different thermophysical properties due to the presence of the additive.

Action:

PoleStar developed a thermodynamic cycle model for a centrifugal chiller and a thermal (heat transfer, fluid flow) model for its evaporator and chilled water pump, to compare baseline electricity usage and other performance parameters between pure water and water with additive in the chilled water loop. The following tasks were performed:

- Cycle model (with the ability to use any refrigerant, including low-GWP next-gen refrigerants and blends from the HFO class), heat exchanger and pump model set-up.

- Simulation of full-load and part-load (50%) chiller operating scenarios without (baseline) and with additive, per the SOW.

Result:

The impact of the heat transfer coefficient enhancement and larger thermal conductivities and densities was estimated at < 1%. This was because of the relatively small impact of reducing thermal resistance on one side of the evap on the overall system performance. This was further due to the fact that temperature approaches in the evap were already only ~2 F (baseline) yielding thermodynamically diminishing returns. EcoLab decided not to pursue the additive development for chillers further.

Client:

Naperville, IL

Project Duration:

3 Months (Feb-Apr 2024)

Project Type:

Thermodynamic, Heat Transfer and Flow Analysis with New Fluid Properties (Refrigerant and Water)

Industry Type:

Global Water Treatment and Process Management Solutions

Business Unit:

R&D

Go-To-Market Strategy and System Engineering Workshop for Expansion Valves of HVAC&R Systems

Problem:

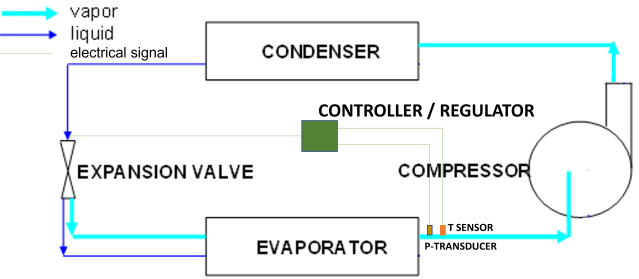

Triton Valves Ltd. is a leading valve component manufacturer in India, supplying to both domestic and overseas automotive and aircraft tire manufacturers as well as HVAC&R equipment manufacturers. In the latter space, falling under climate technologies, Triton has thus far focused on high-quality, low-cost service valves. They would now like to move up the value ladder to supplying more critical components at the core of HVAC&R systems and crucial to their fundamental function and performance. Such components should, however, possess adjacencies with their core business and play off Triton’s strengths, such as expansion valves.

To this end, Triton needs to develop an understanding of the HVAC&R industry, players, products, technologies, thermodynamics, competencies and competitive landscape, as these impact expansion valve innovation and new product introduction. Based on the understanding, business and product development strategies can be formulated and multi-generational product plans can be defined.

Action:

PoleStar Consulting conducted a workshop / training with Triton’s R&D, design and manufacturing engineers to go over the fundamentals of HVAC&R systems, the expansion valve component – both form and function, the product development process, and system engineering as a methodology for requirements-based design and verification at the heart of product development.

Thereafter, PoleStar had a series of discussions with senior leaders of the company to describe the industry ecosystem and key players – both system OEMs (especially in the North American market) and established valve suppliers (globally), pressing (unmet) needs in the industry, and typical barriers to entry.

Last but not least, PoleStar made an assessment of the company’s systems, processes and capabilities via a comprehensive tour of the facilities and meeting with personnel in various functions. Armed with this assessment, PoleStar proffered recommendations to the company’s leaders on a go-to-market strategy and positioning, including product/technology for market entry, potential OEM joint development partners (and ultimately customers), and core competency building and associated recruiting.

Result:

Triton Valve engineers and leaders have a sound understanding of how they are positioned to enter the global HVAC&R market with a higher-value valve product – one that is of high quality and low cost. Such a product will help HVAC&R OEMs in developing highly energy-efficient and reliable, but cost-effective, systems such as heat pumps that have lower emissions and hence help with the decarbonization of buildings. Triton leadership has PoleStar’s recommendations for next steps in identifying a viable entry product and geography, establishing a product development program and joint development partnerships, and recruiting for core competencies to support the program. Further, longer-term engagement between Triton and PoleStar is being planned to execute on these steps.

Client:

Bangalore, India

Project Duration:

1 Week (Jan 2024)

Project Type:

Business and Product Development Strategy, Workshop/Training

Industry Type:

Component Manufacturer/Supplier for Automotive, Aircraft and HVAC&R

Business Unit:

Senior Leadership, Engineering/R&D, Manufacturing

Data Processing and Visualization Tool for Heat Pump Field Trials

Problem:

Over 2018-2020, GTI Energy tested a number of prototype residential absorption heat pumps developed by a Tennessee manufacturer in the field (attached to people’s homes and intended to demonstrate seasonal heating performance). PoleStar Consulting was hired to develop a data processing and visualization tool to manage the data coming from the disparate sources (heat pumps units) and provide analytical abilities for reconciliation of the differences in energy performance between the units.

Action:

PoleStar researched the data visualization landscape, selected Microsoft’s PowerBI, and developed and delivered a powerful analytical tool / user interface for the above purposes using this platform.

Result:

GTI was able to use this tool post-commissioning to analyze the field trial units, and arrive at useful conclusions regarding performance differences and the bases for those. This information could then be fed back to the design team for improvements in the hardware design and controls. It also gave confidence in the readiness of the technology for large-scale deployment (TRL), which greatly benefitted the Tennessee manufacturer in their scale-up and overall strategic planning.

Client:

(GTI Energy), Chicago, IL

Project Duration:

5 Months (Nov 2019-Mar 2020)

Project Type:

Data Visualization and Analysis

Industry Type:

Energy & Utilities

Business Unit:

Engineering & Technical